Bio Diesel Processor Bio Pro 190

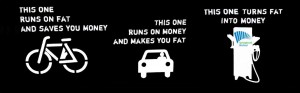

Producing bio-diesel from waste cooking oil

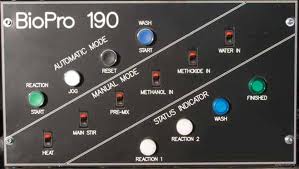

The BioPro™ 190 and The BioPro™ 190EX convert organic oils into an alternative-to-diesel fuel called Biodiesel through a chemical process. The common name for this process is called an acid/base catalyzation. This means that the oil is chemically altered to allow it to run in any unmodified diesel engine.

What’s unique about the BioPro™ system is that the majority of this process is done by the machine, in an automated process, with very little user interaction. Instead of having to turn valves, meter in chemicals, and carefully monitor the machine, you simply pour everything in, press a button and walk away.

Before starting the process, the user fills the machine with 50 gallons of filtered, dewatered oil. (The machine will also assist in dewatering if necessary). The oil can be any organic oil including tallow, fats, vegetable oil, etc. (The BioPro™ will not convert mineral or motor oils.) Currently, waste vegetable oil collected from kitchens and restaurants is the most commonly used feedstock by BioPro™ owners, however, a vast variety of virgin oils may also be used.

After filling the machine with oil, the user then fills the machine with a predetermined amount of catalyst and methanol. The catalyst is easily weighed and placed in the machine. The methanol is then added to the machine. The final step is to measure out the proper amount of sulfuric acid. The user then presses “The Big Green Button”, waits for the mixing to start and then pours the sulfuric acid into the machine. Then the user walks away, allowing the machine to do its work. There is no need to monitor the machine. It does the majority of its work all by itself!

After the button is pushed and the machine is started, here’s a breakdown of how the machine converts the oil feedstock into clean, crystal clear, ready to use Biodiesel.

REACTION 1 – ESTERIFICATION a.k.a. the “Acid” stage During this stage, the machine mixes sulfuric acid and a portion of the methanol into the oil. The sulfuric acid goes on the hunt for free fatty acids and modifies them so that the methanol can attach to them and create biodiesel.

Over the course of a few hours a lot of heating and mixing will occur to make sure that the acid and the methanol have had a chance to do their job. This is done because a thorough Acid stage helps to make the Base stage successful.

REACTION 2 – TRANSESTERIFICATION a.k.a. the “Base” stage After the acid stage has occurred it ‘s time for the real action to get started. In this stage the machine mixes in the Base catalyst and the rest of the methanol. During this stage, the catalyst, which is usually Lye (Sodium Hydroxide – NaOH) or Caustic Potash (Potassium Hydroxide – KOH), attacks the oil and begins breaking the molecules apart into glycerol and fatty acid chains (the catalyst used is extremely powerful). Immediately after the molecules are broken apart, the methanol begins to attach to the fatty acid chains. This causes the glycerol molecules to begin to drop out of the oil into a mixture called glycerin.

This stage also takes several hours to occur. While this stage is happening the machine is mixing the oil, chemicals, and methanol together with an extremely powerful, tri-blade impeller. This helps to vigorously mix fluids and chemicals together and helps to ensure that all of the oil has a chance to be chemically altered.

SETTLING PERIOD – a.k.a. Glycerin Drop Out After both reactions have occurred, the oil is allowed to settle for a period of time. This allows the glycerin to fall to the bottom of the tank and separate away from the freshly made biodiesel. The settling can take several hours and helps to ensure that everything settles out properly.

MID POINT – DRAIN GLYCERIN At this point, the user comes back to the machine and drains out the settled glycerin and begins the washing cycle. This is the only user interaction required during the processing.

MID POINT – DRAIN GLYCERIN At this point, the user comes back to the machine and drains out the settled glycerin and begins the washing cycle. This is the only user interaction required during the processing.

WASHING BEGINS The BioPro™ now begins the washing part of the process. During this process, the machine will turn on the heat and lightly spray a mist of clean, fresh water into the biodiesel to begin the process of cleaning the biodiesel. It may sound strange to add water to biodiesel, but it works. Because water is heavier than biodiesel, it quickly falls to the bottom.

As the water falls, excess methanol and soap molecules attach to the water and fall with it, thereby cleansing the biodiesel. After the first mist wash, the water is then drained out and another mist wash is performed, only this time the big tri-blade mixing impeller comes on mixing the water and the biodiesel together to create a powerful washing action. We call this an “agitated wash cycle”. It mixes the water thoroughly with the biodiesel so that it can pull as many impurities as possible out of the biodiesel.

The machine then lets everything settle for a few hours, drains off the water and starts another agitated mist wash. In an effort to thoroughly cleanse the biodiesel, the machine performs this last wash cycle with the tri-blade impeller going at full force. Once it’s done, the water settles to the bottom and is automatically pumped out by the machine.

DRYING BEGINS Now the final settling stage begins. After the wash water has been drained off, the heat remains on and the tri-blade impeller kicks in again. The combination of the heat and the mixing help to evaporate any excess water from the freshly washed biodiesel. After the heat and mixing is done the BioPro™ allows the biodiesel to settle out one last time. During this time, the now heated biodiesel evaporates off any excess water. When the process is complete, you’re left with a nice, clear looking tank of biodiesel that is ready to use!

That’s all there is to it. Instead of having to transfer everything around from container to container, the machine does it all for you. When it’s completed, you can hook up the hose to the included fuel pump and pump the finished biodiesel right into your vehicle.

DRYING BEGINS Now the final settling stage begins. After the wash water has been drained off, the heat remains on and the tri-blade impeller kicks in again. The combination of the heat and the mixing help to evaporate any excess water from the freshly washed biodiesel. After the heat and mixing is done the BioPro™ allows the biodiesel to settle out one last time. During this time, the now heated biodiesel evaporates off any excess water. When the process is complete, you’re left with a nice, clear looking tank of biodiesel that is ready to use!

That’s all there is to it. Instead of having to transfer everything around from container to container, the machine does it all for you. When it’s completed, you can hook up the hose to the included fuel pump and pump the finished biodiesel right into your vehicle.